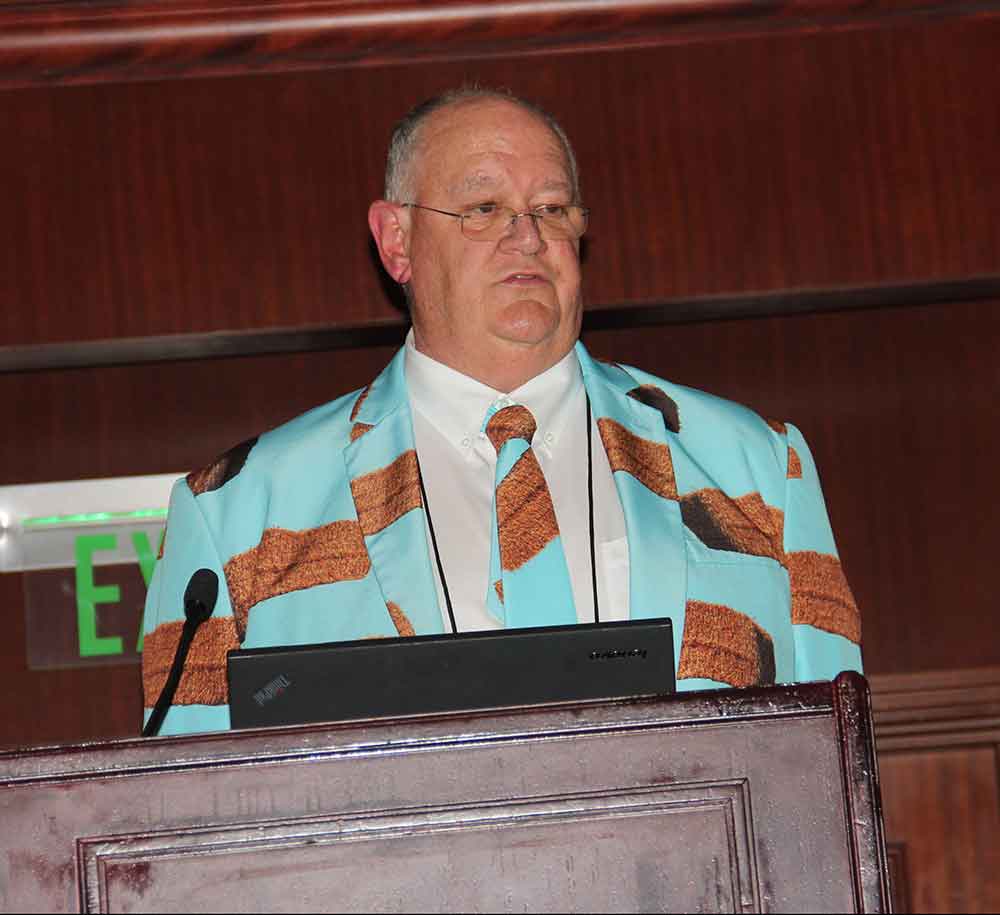

Alan Douglas Brett, who in the latter half of his career led the international advertising sales growth of Panel World magazine, and whose vigorous life included professional motor cycle speedway racing as a young man and a long stint as sales manager with the Daily Telegraph in London, died January…

SmartLam Teams With RedBuilt

SmartLam Teams With RedBuilt

SmartLam North America and RedBuilt announced a partnership to supply cross-laminated timber (CLT) products and solutions to architects, engineers and contractors for projects using the mass timber building technology.

RedBuilt will serve as exclusive distributor of SmartLam CLT in the Pacific Northwest, West Coast and Southwest, which includes nine states: California, Oregon, Washington, Idaho, Nevada, Arizona, New Mexico, Utah and Montana.

The companies state they will offer the first integrated solution for mass timber building, with highly trained technical sales and design teams, all deeply familiar with mass timber design, manufacturing and installation. “These teams will guide architects, engineers and contractors through the entire design and construction process to streamline workflow and eliminate guesswork.”

The SmartLam/Redbuilt partnership will offer a wide array of structural engineered wood solutions, including CLT, GLB, Open Web, I-joists, LVL and connection hardware from a single source, simplifying the building process.

Since establishing North America’s first CLT manufacturing facility in 2012, SmartLam has been a pioneer of CLT in the U.S. SmartLam operates two modern production facilities in Columbia Falls, Mont. and Dothan, Ala. The Columbia Falls facility also serves as corporate headquarters.

Casey Malmquist, CEO and Founder of SmartLam North America, is thrilled about this partnership. “SmartLam sees great potential in developing the market though our partnership with RedBuilt. Our team is excited to support and grow the relationship by offering the absolute best products, unmatched service levels, and seamless project delivery to our joint customers throughout the Western U.S.”

Since 1958, RedBuilt has been an industry leader in innovative and customized, wood building solutions. Headquartered in Boise, Idaho, RedBuilt operates four manufacturing plants, five design centers, with technical sales team members posted around the country to provide local support.

Don Schwabe, CEO and President of RedBuilt, shares the excitement and benefits of the partnership. “Mass timber is a natural extension to the RedBuilt offering, and Smartlam is the natural choice as our supplier. Our customers are getting the best of both worlds. From design to delivery, they know we will get it done on-time, on-spec, and on budget.”

SmartLam has announced plans to build several CLT facilities across the country.

RELATED ARTICLES

SOMETIMES THE PATHS COME FULL CIRCLE

Latest News

Brett Helped To Pave Way For Panel World

U.S. Housing Starts Dip Slightly In November

U.S. housing starts (combined single-family and multi-family) showed a slight decline in November, coming in at a seasonally adjusted rate of 1.427 million, 0.5% below October, and 16.4% below starts in November 2021, according to the U.S. Census Bureau and U.S. Dept. of Housing…

Raute Restructures, Announces Personnel Changes

To better address its operational and strategic development plans, Raute is changing its organizational structure, which will strengthen Raute’s ability to service customers and streamlines internal operations. The change will also be reflected in the…

Roseburg Orders Super-Long Dryer

Roseburg Forest Products has ordered a veneer dryer for its plant in Coquille, Ore. from Westmill. At 204 ft. length, the dryer will be the longest veneer dryer in North America, according to the participants. The 6-deck, steam-heated jet dryer is designed to dry the heaviest moisture Douglas fir, hemlock and spruce…

Find Us On Social

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

One of the many intriguing tales to emerge from the

One of the many intriguing tales to emerge from the