Rosboro Advances With GlulamMajor glulam producer Rosboro Co. named several primary suppliers for its upcoming $100 million-plus expansion project in Springfield, Ore. The investment includes a lamstock planer mill, expanded dry kiln capacity and a new glulam plant....

Rosboro Advances With Glulam

Rosboro Advances With Glulam

Major glulam producer Rosboro Co. named several primary suppliers for its upcoming $100 million-plus expansion project in Springfield, Ore. The investment includes a lamstock planer mill, expanded dry kiln capacity and a new glulam plant. The company currently produces glulam at Springfield and has been producing glulam for decades.

USNR is performing the dry kiln expansion and will provide the primary components for the new planer mill, including a USNR Model 4200 planer and transverse high grader (THG) with Deep Neural Networks.

The glulam factory will be delivered by Stiles Machinery, Kallesoe Machinery and SystemTM—all members of the Homag Group. The layout will include a high-efficiency lumber infeed and fingerjointing line that is seamlessly integrated with two high-capacity radio frequency press lines.

Chambers Construction of Eugene, Ore. will oversee design and construction of approximately 225,000 square feet of new buildings and associated infrastructure developments.

Contrary to recent reports, no new sawmill is planned, as the company already has two sawmills. One has been producing primarily lamstock, and the other, a small log stud mill, will be converted into a lamstock mill. Rosboro expects the sawmills will have adequate capacity to produce lamstock for glulam production, and doesn’t expect any increase in log consumption as the operation shifts from commodities to a value-added product.

Construction has begun, and the company expects the projects to be fully operational in 2026.

Latest News

Rosboro Advances With Glulam

Interfor to Exit Operations In Québec

Interfor to Exit Operations In QuébecInterfor has announced plans to exit its operations in Québec, Canada, including the sale of its three manufacturing facilities and the closure of its Montréal corporate office. This strategic initiative will support a focus on the...

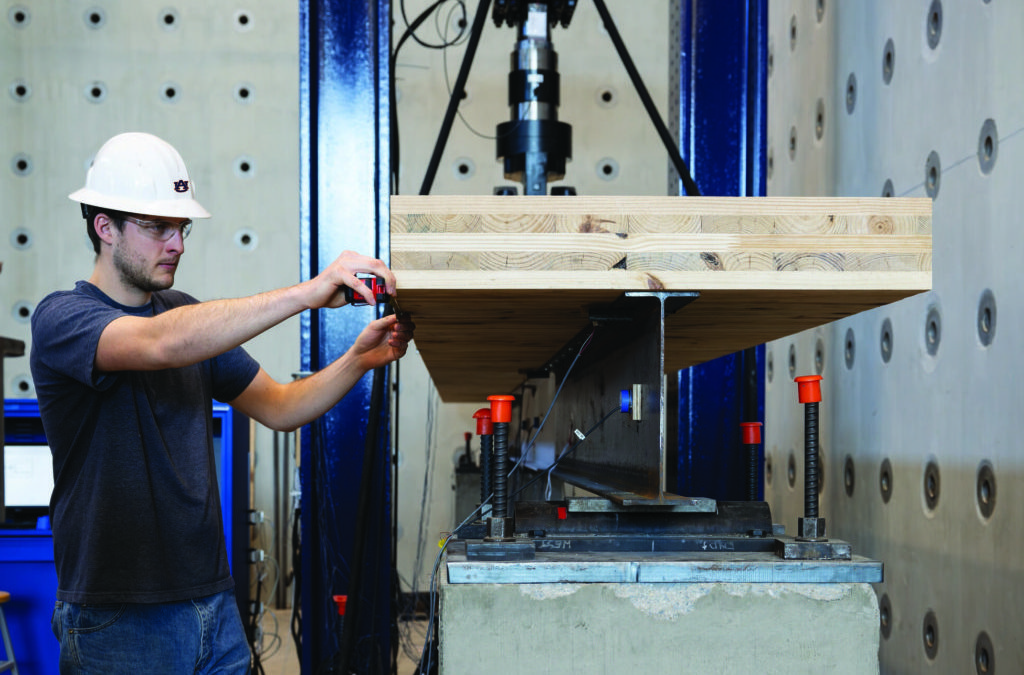

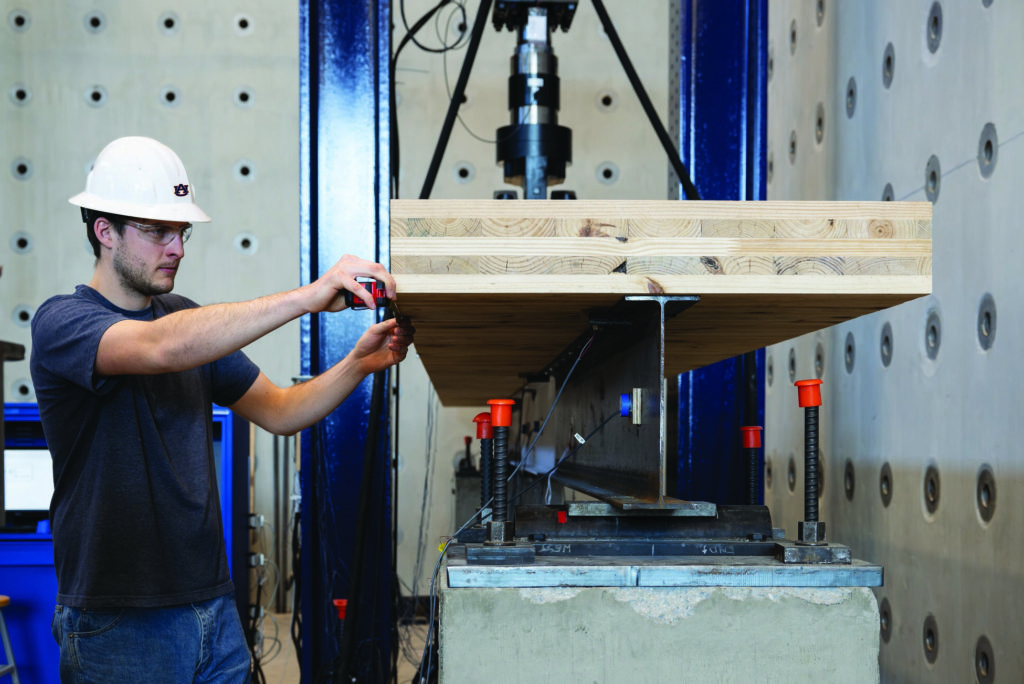

Auburn University Announces Agenda For CLT Conference

Auburn University Announces Agenda For CLT ConferenceThe Auburn University College of Forestry, Wildlife and Environment (CFWE) has unveiled its roster of speakers and conference agenda for the upcoming 2024 cross-laminated timber (CLT) conference to be held this...

Find Us On Social

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!