RedBuilt Appoints Ted Osterberger As CEOHampton Lumber and affiliate, RedBuilt, are pleased to announce the appointment of Ted Osterberger as Chief Executive Officer of RedBuilt, effective June 1, 2025. Osterberger succeeds Don Schwabe, who will retire later this year...

Kirk Blanchette To Lead Huber Engineered Wood

Kirk Blanchette To Lead Huber Engineered Wood

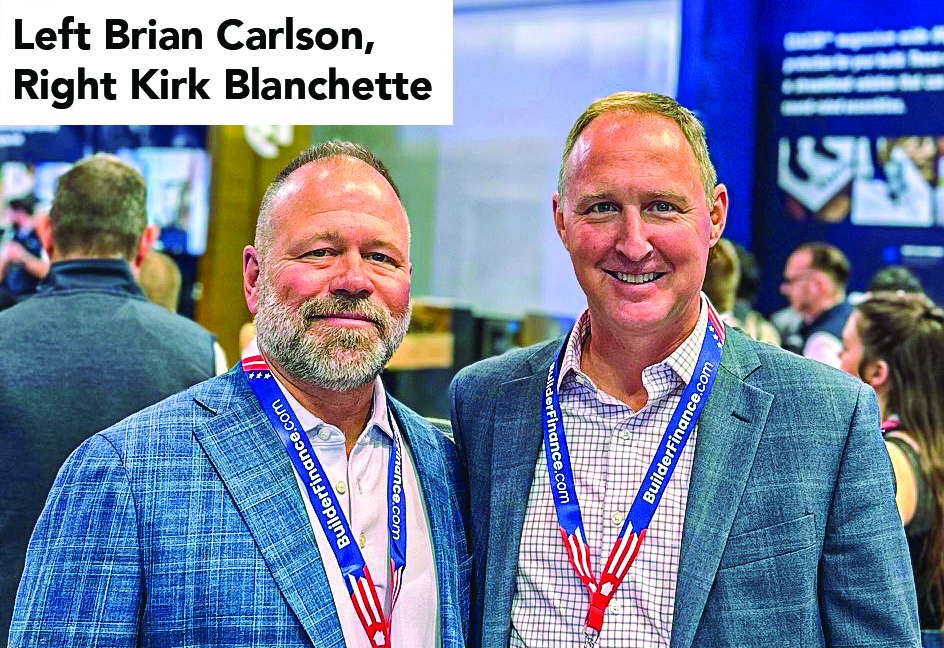

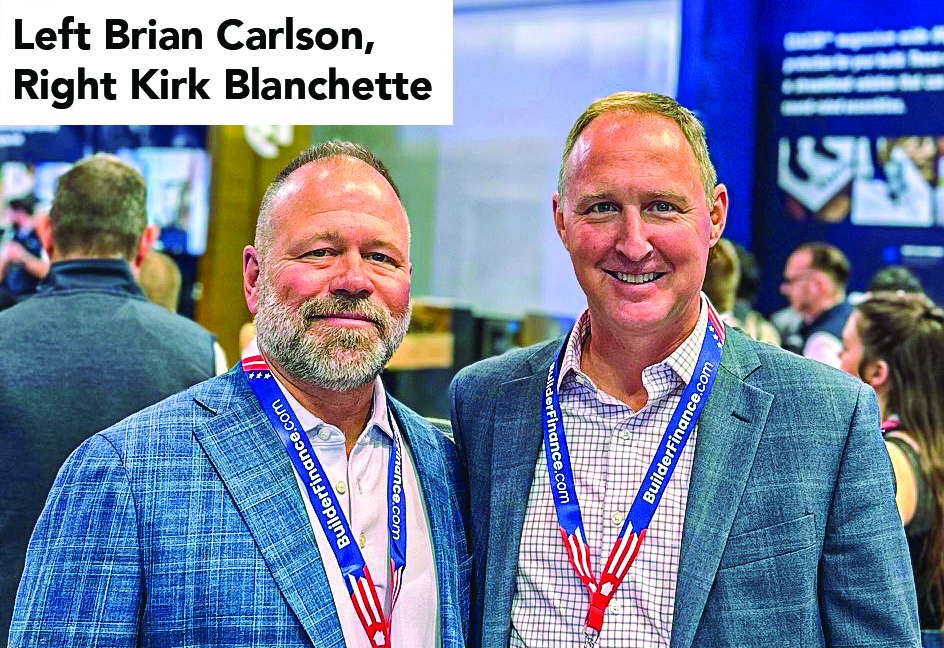

Huber Engineered Woods (HEW) has announced that Kirk Blanchette will become President of HEW, succeeding Brian Carlson, who is retiring as of July 1.

Huber Engineered Woods (HEW) has announced that Kirk Blanchette will become President of HEW, succeeding Brian Carlson, who is retiring as of July 1.

Blanchette will bring more than 25 years of experience in finance, corporate strategy and leadership to the role. He is currently Chief Financial Officer & Vice President of Strategy for HEW. In addition to currently leading the marketing, strategy, finance & accounting, purchasing and risk functions for HEW, he previously had responsibility for the logistics, sales and operations planning, inside sales, information technology and industrial/OEM functions as well.

Prior to joining HEW in 2012, Blanchette held numerous roles in the venture capital and private equity industries, most recently as a Partner at Seguin Partners, a middle-market-focused fund. Prior to his principle investing roles he was an investment banker with Bank of America focused on mergers & acquisitions and corporate finance for industrial clients.

He holds a Bachelor’s Degree in Finance and Investments from Babson College and an MBA from the Wharton School of the University of Pennsylvania.

“I am honored to step into this role and continue building on the foundation of success established by Brian Carlson and our incredible HEW team,” Blanchette says. “As a family-owned business, we remain committed to our core values—the Huber Principles—and our valued employees and customers. I look forward to leading the organization to deliver outstanding results for our customers and shareholders into the future.”

Carlson adds, “This is an exciting time for our entire organization. Kirk is well prepared to lead HEW into its next era, where it will keep delivering innovative, sustainable building solutions that address the needs of our customers and the North American housing and construction industry at large.”

Latest News

RedBuilt Appoints Ted Osterberger As CEO

Hardwood Plywood Coalition Files Trade Petitions Against Asian Imports

Hardwood Plywood Coalition Files Trade Petitions Against Asian ImportsWashington, D.C.-based law firm Wiley, on behalf of the Coalition for Fair Trade in Hardwood Plywood, has filed antidumping (AD) and countervailing duty (CVD) petitions with the U.S. Department of...

Andritz Acquires LDX Solutions

Andritz Acquires LDX SolutionsAndritz has acquired LDX Solutions, a provider of emission reduction technologies and related services in the North American industrial market, with annual revenues of about $100 million. This acquisition further strengthens Andritz’s...

Find Us On Social

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!