by Web Editor | Nov 15, 2004

Panel World’s November issue spotlights Colville Indian Power and Veneer, which has upgraded and started up the softwood plywood facility at Omak, Wash. An article discusses the new EPA MACT emissions rule so that mills can understand their options. Also featured is LP’s LVL/Plywood operation at Golden, BC, since it has earned a high performance reputation.

by Web Editor | Sep 15, 2004

Panel World’s September issue spotlights GreenTech Panels, which has started up a post-consumer waste wood-based particleboard plant in Minden, La. with a reconditioned Mende press. Also featured is Besse Forest Products Group, which has revamped and expanded its flagship veneer facility. An article from a Siempelkamp writer who toured three Duratx plants in early 2004 highlights how Duratex operations in Brazil reveal versatility.

by Web Editor | Jul 15, 2004

Panel World’s July issue spotlights Ga.’s Langboard Inc., which, thanks to a strong OSB market, has been able to bring its three-phase OSB expansion along at a controlled pace. Nexfor Inverness OSB plant is featured for maintaining its leadership position as it leads the battle for market share. An article highlights how OSB producers are enjoying record prices and looking toward a new round of expansions.

by Web Editor | May 15, 2004

Panel World’s May issue spotlights Warm Springs Composite Products, which has quietly been growing an efficient custom fiber cement stock and cut-to-size operation in Warm Springs, Ore. Also featured is MDF Hallein, which has encountered stringent environmental requirements at their MDF plant. An article discusses how Boise plants are benefiting from innovative emissions control systems.

by Web Editor | Mar 15, 2004

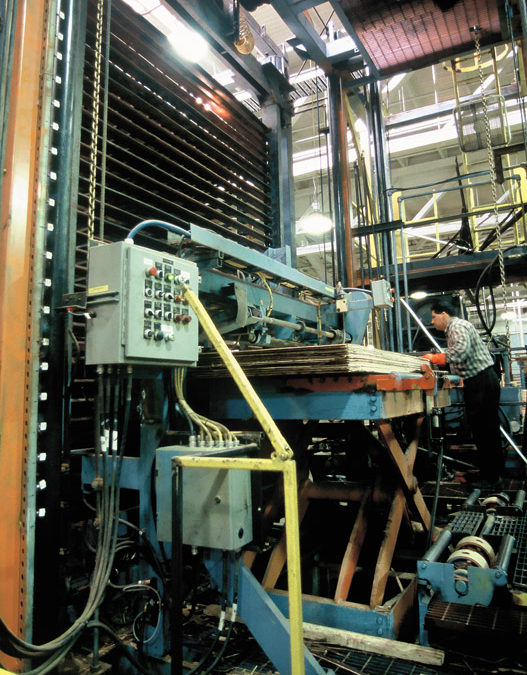

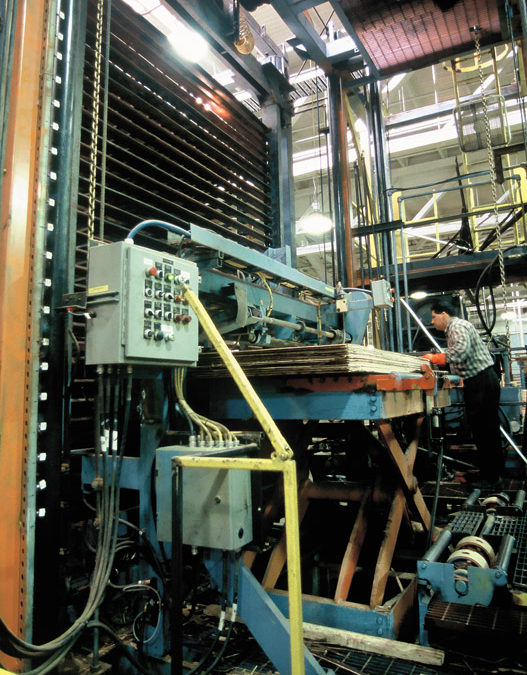

Panel World’s March issue spotlights Richmond Plywood, which maintains a policy of constant machinery and technology upgrading at its softwood plywood mill in British Columbia. Also featured is Louisiana-Pacific, which is pursing an aggressive investment program at OSB mills, including its Hayward facility. “At the Core” discusses the family roots that still drive the manufacturer Dieffenbacher.