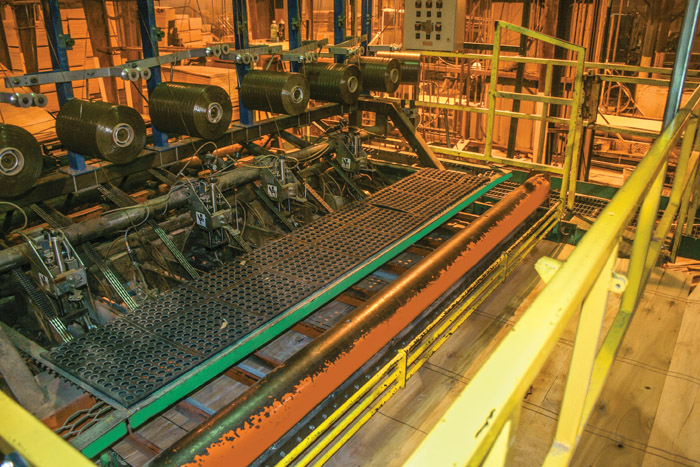

Panel World’s September issue discusses how Louisiana-Pacific Corp. keeps its sights set on employee safety and becomes an industry leader. Quality control capability expands and impacts global standards. A high speed automatic repair line was installed at the Arauco plant in Horcones. Also, Quebec’s Boisaco formed the Granulco division at the depths of the recession.