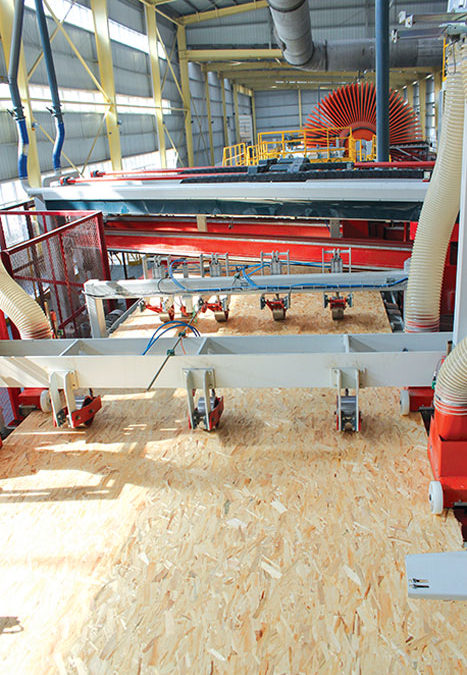

Panel World’s November 2015 issue features a special article by Dr. Frederick Kurpiel and Dr. Hui Wan highlighting the growing OSB industry in China and the plant at Hubei Baoyuan. Also featured is Roseburg, Oregon’s Nordic Veneer and their commitment to innovation and high quality. Other articles cover the latest industry news, new projects, new products and technology, the 2015 Editorial Index, and upcoming events.