May 2023

May 2023

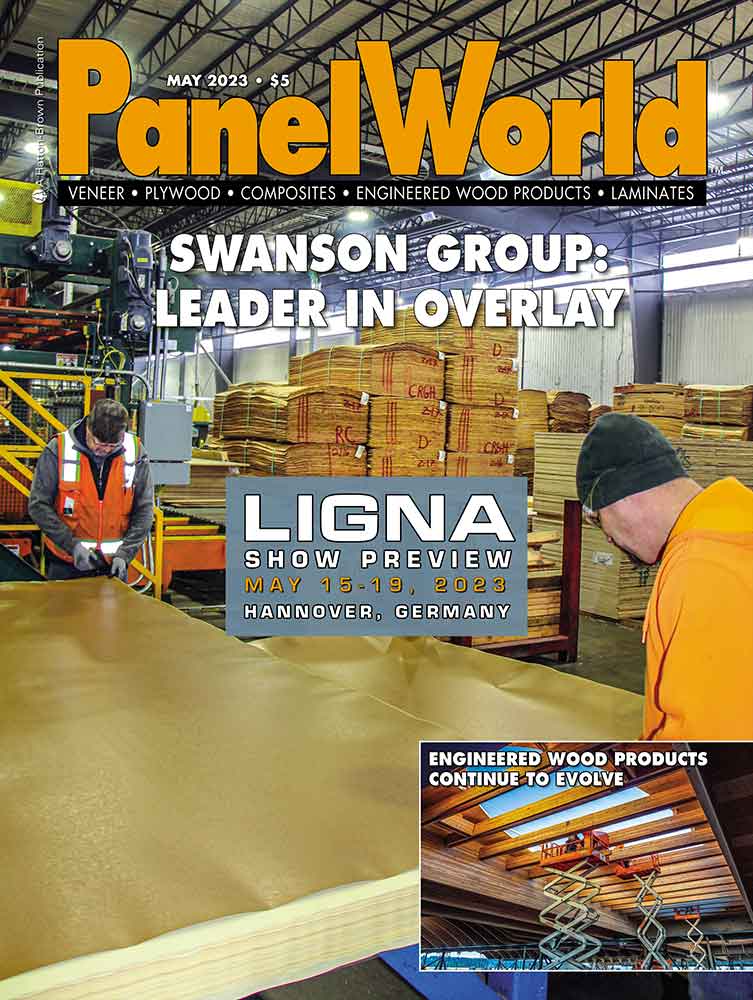

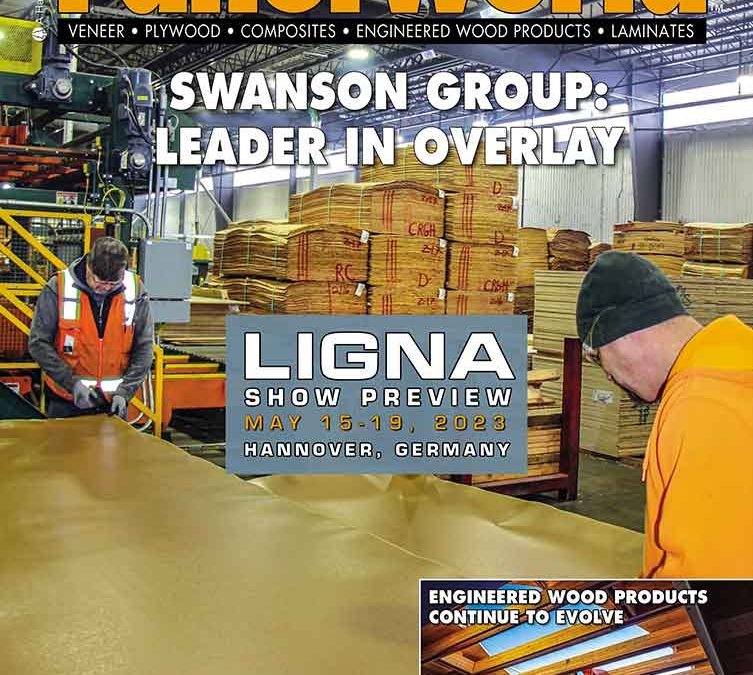

Cover: Swanson Group: Leader In Overlay

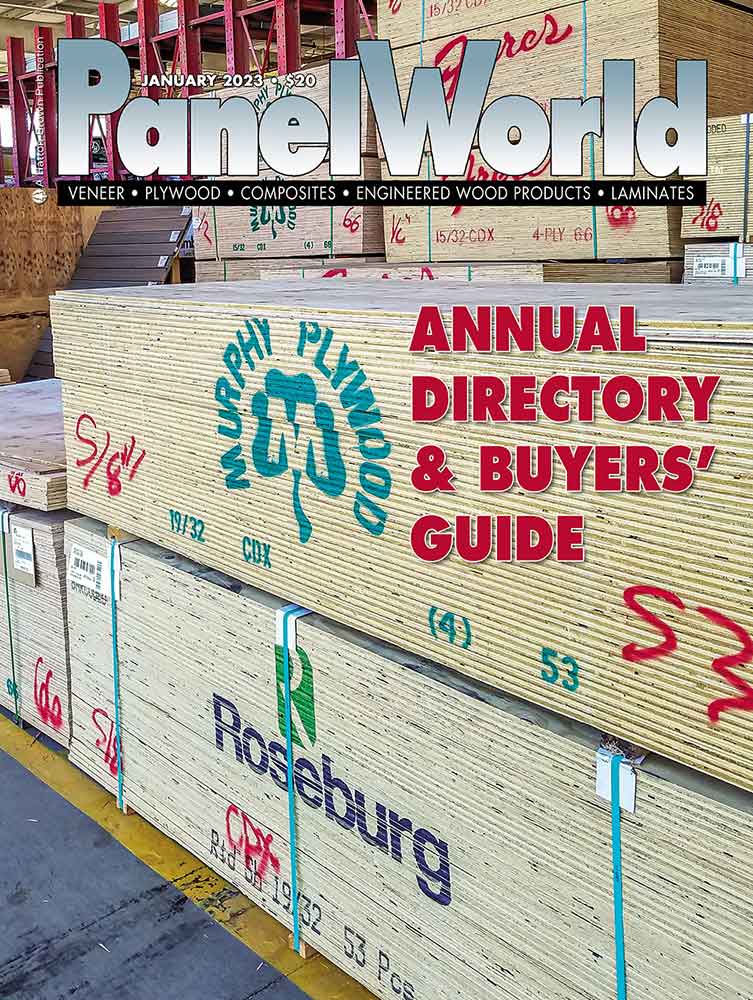

SPRINGFIELD, Oregon – Closely watched as one of two major plywood plant rebuild projects following disasters in 2014—a tornado at a plant in Mississippi in April and a fire at Swanson Group’s plant here in July—the Swanson plywood plant here really hit its stride several years ago after becoming fully operational in 2017, says Swanson Group President and CEO Steve Swanson. The facility is a top supplier of HDO and MDO plywood products and a top tier plywood producer overall.

Inside This Issue

TAKING STOCK: Time To Stretch The Legs

In May, I depart for my 17th consecutive Ligna in Hannover, Germany. If the pandemic hadn’t canceled the event in 2021, I suppose this would have been 18. Regardless, I’m sure by now you’re thinking this guy must be getting up in years.

I know there must be many other Americans who have a longer consecutive Ligna attendance streak than me. But I know of only one—Fred Kurpiel, who is co-chairman with me of the PELICE event held in the off-Ligna year, and who had stints with Siempelkamp and Imeas in addition to his long-ongoing academic and consulting work.

Article by Rich Donnell, Editor-in-Chief, Panel World

UPDATE

- Roseburg Announces Massive Investment

- Dates Announced For Ninth PELICE

- Mercer Gains CLT Contract

- Particleboard Site Will Host Pellet Mill

Ligna

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements placed in Panel World May 2023 with regard to the Ligna event in Hannover, Germany, May 15-19.

- Andritz

- Anthon

- Argos Solutions

- Baumer

- Biele Group

- Büttner

- CERATIZIT

- CMC Texpan

- Con-Vey

- Cross Wrap

- Dieffenbacher

- Dunhua Bytter Technology

- Dürr Systems

- Electronic Wood Systems (EWS)

- Fagus GreCon

- Grenzebach

- Hymmen

- IMAL PAL Group

- IMEAS INTEC

- IPCO

- John King Chains

- Ledinek

- LIMAB

- Longoni Roberto

- Meinan Machinery Works

- MINDA

- Modul Systeme

- MoistTech

- MUNZING

- Omeco

- Pallmann

- PESSA

- Plytec

- Siempelkamp

- stela Laxhuber

- Taihei Machinery Works

- USNR

- Wemhöner

- Willamette Valley Company

Assessment Of The Ever Evolving Engineered Wood Industry In 2023

EDITOR’S NOTE: This is the first part of a two-part series. The first part is intended to update current products and performance of the North American based Engineered Wood Products (EWP) industry, with a focus on the Mass Timber products of Cross Laminated Timber (CLT) and Mass Ply Panels (MPP). The second part will analyze and forecast market trends, and discuss emerging products and new processes designed to better meet construction needs. Throughout, the two installments will outline the key role that the EWP industry plays in providing cost-effective, environmentally sustainable, and innovative wood products that meet market needs better than conventional solutions.

Article by Richard (Dick) Baldwin, Frederick T. Kurpiel, Richard (Rich) Baldwin

PROJECTS

- Sonae Arauco Plans New Production Line

- Arauco Announces MDF Plant In Mexico

- India’s Greenpanel Grows With MDF

- Jiangxi Luli Goes With Stela Drying

- Metro Ply Brings In First Board

- Con-Vey Names Product Manager

- Raute Appoints Moilanen As CPO

- Dieffenbacher Names Energy Unit Director

SUPPLY LINES

- WMF Returns To Shanghai

- Raute PRS R5 Proving Itself

CLIPPINGS

- Hunt Forest Products Supports Innovation Center

- Roseburg Adds Russ To Commercial Team

- Sonae Arauco Beefs Up Sales/Marketing

- Roseburg Builds Executive Team

- Simsboro Mill Noted For Safety

- SNA Adds Rupp As Senior Recruiter

- GP Contributes To CLT Project

Find Us On Social

Swanson Group: Leader In Overlay

Article by Dan Shell, Senior Editor, Panel World

SPRINGFIELD, Oregon – Closely watched as one of two major plywood plant rebuild projects following disasters in 2014—a tornado at a plant in Mississippi in April and a fire at Swanson Group’s plant here in July—the Swanson plywood plant here really hit its stride several years ago after becoming fully operational in 2017, says Swanson Group President and CEO Steve Swanson. The facility is a top supplier of HDO and MDO plywood products and a top tier plywood producer overall.

After announcing the rebuilding project in January 2015, the Swanson Group sought to get the facility back up ASAP. Considering the economic climate and overall market strength, Swanson says it was a bit of a “desperate time” for the company, and he couldn’t build the mill “by just throwing everything at it” like major capital projects in the past.

As the mill started up in 2016 and first began peeling, Swanson leveraged production immediately, first selling green open market veneer, then dry veneer as the various production equipment came on line.

“Finally we started laying up some product (late 2016), but all the while we were trying to preserve our market share in overlay,” Swanson says. During construction the company had leased the old Pacific States Plywood plant nearby to make some basic, one-step overlays. Not the best idea, since the facility wasn’t designed for it, he says. “But we were able to make some product there.”

Swanson also moved a small amount of overlay production to its Glendale, Oregon commodity plant. Again, both situations were less than ideal, but the commitment to the overlay market remained.

The same commitment has come into play more recently: As sheathing prices skyrocketed several years ago, Swanson could have halted its overlay program, reduced costs and chased the market with almost all sheathing products.

Some of the sales staff wanted to do just that, but the company didn’t. “Instead, we stayed with our overlay program and actually increased our overlay market share during that time,” Swanson says, adding that many mills that had dabbled in overlay products made the switch to sheathing, which provided more of an opening to expand overlay output.

“We gradually increased prices as costs have gone up, and we have maintained a margin in that product,” Swanson says. “I think today we’re the largest overlay producer in North American, certainly from a single facility.”

Want More Content?

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!