November 2025

November 2025

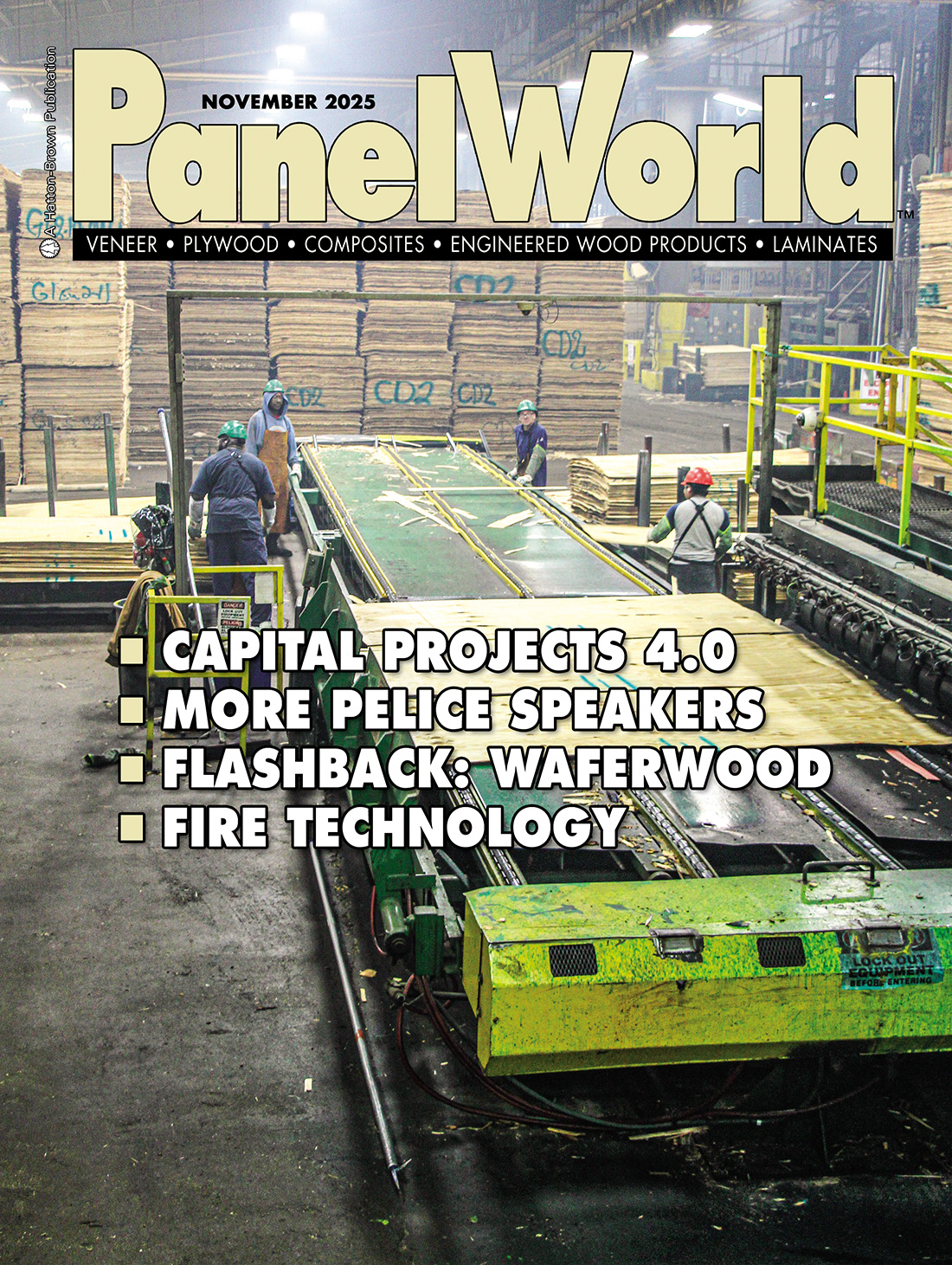

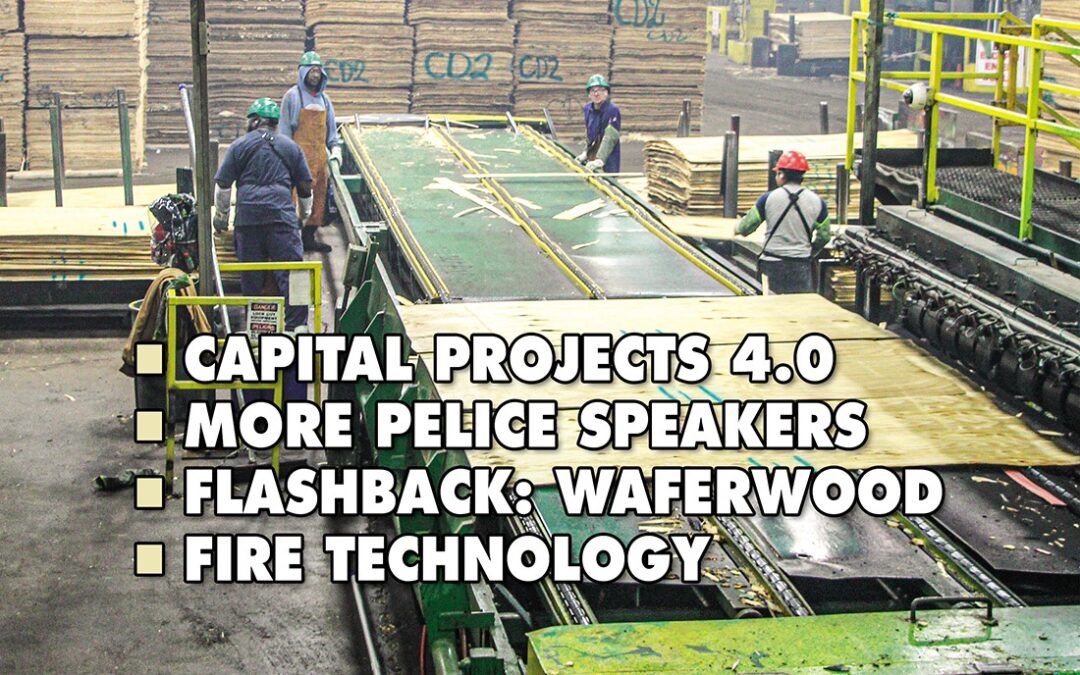

COVER: Capital Projects 4.0 and More!

Some action from Winston Plywood & Veneer’s operation in Louisville, Miss. serves as the backdrop for the cover of, believe it or not, the final issue of Panel World in 2025— an issue that has a little bit of everything in it.

Inside This Issue

Capital Projects 4.0

- More PELICE Speakers

- Flashback: Waferwood

- Fire Technology

Some action from Winston Plywood & Veneer’s operation in Louisville, Miss. serves as the backdrop for the cover of, believe it or not, the final issue of Panel World in 2025— an issue that has a little bit of everything in it.

SUBSCRIBE TO PANEL WORLD TODAY TO GET YOUR COPY OF THE ANNUAL DIRECTORY & BUYERS’ GUIDE

UPDATE

- Potlatch-Deltic, Rayonier To Merge

- Roseburg Exits Hardwood Plywood

- EUDR Proposal Causes Questions

- USDA Focuses On Wildfire Risk

- Letters Urge Trump Forward

- USFA Supports Private Landowners

Supply LINES

- EWS’ Mays Receives Mark Hatfield Award

- Evergreen Celebrates 40

- Westmill Names Kenny as VP

- Pressure Treating Team Moves Forward

CLIPPINGS

- Brassard Receives Brock Landry Award

- TimberHP Produces Timberboard

- Weyerhaeuser Taps Buckhannon

- Agency Awards Bioenergy Grants

PROJECTS

- Three USNR Veneer Dryers Start Up

- Sonae Aarauco Goes With Recycling

- Nordic Installs Largest MPDS

- Columbia Looking At Firebox

- Element5 Installs MiCROTEC Scanner

Find Us On Social

A Good Time To Have A Good Time

Article by Rich Donnell, Editor-In-Chief, Panel World

You have to give APA—The Engineered Wood Assn. a lot of credit. They know how to host a party in luxurious locations, such as the recent annual meeting in Phoenix, Ariz. at the Sheraton Grand at Wild Horse Pass. What a name!

It makes a lot of sense. Even when markets are soft—as everybody was talking about—how disheartened can you re- ally feel, when you’re about to play 18 holes at the beautiful Whirlwind Golf Club, play a little pickle ball, do some cripple coot shooting, or, as in my case, hike the 2.5 mile interpretive trail along the Gila River, which was sort of spooky with the ghosts of Native Americans who had lived and camped there running around everywhere. The coolest sign on the trail I read was the one that said at least 45,000 California Gold-Rushers had passed this way heading West.

And then of course there was the nearby Gila River Casino, which I didn’t frequent and out of which I did not hear any stories of any APA annual meeting participants striking it rich, or losing everything. But I could be wrong.

The receptions and food functions and exhibit sessions were all very good, and the 400 or so people in attendance didn’t skip any of them.

As usual, the event hosted a Monday morning general session, and—given those soft markets again—the mood was pretty much can we get through the discussions about the soft markets and head back outside?

Outgoing APA Chairman Doug Asano, who is senior VP, Sales & Marketing at Roseburg, moderated a panel session that included James Finucane, senior economist and VP at Swiss Re; Doug Duncan, retired chief economist at Fannie Mae; and Kevin Walsh, associate professor and director of the master of engineering program at Notre Dame.

Finucane, speaking on “Insurance and Resilience,” said a couple of things that stood out: In 2024 U.S. insurers paid $150 billion in property claims, accounting for 10% of private construction spending. And major insurers have increased rates while pulling back from higher-risk properties, resulting in areas where the government-backed plans are now the only option for many consumers.

Economist Duncan noted there were 27 separate billion-dollar weather and climate disasters that impacted the U.S. in 2024. He cited some fairly obvious points about building resilient homes, such as assessing materials properties and performance; understanding construction and supply side cost considerations; analyzing insurance and demand side risk factors; and evaluating house pricing relative to resilience features and affordability.

Walsh got into the weeds a little bit on the four elements of risk—hazard, exposure, vulnerability and consequence, and actuarial catastrophe modeling, and noted that in 2022 there was roughly $200 billion of global damage costs from natural disasters. Basically he said we should continue to invest in post-disaster structural and analytical evaluations and improve the “fragility curve.”

Also during the general session, APA awarded the Bronson J. Lewis Award to Jim Enright, he most recently the president and CEO of PWT (Pacific Woodtech), but with a career that spanned through several great wood products companies and included substantial work as an APA trustee and board member.

And back to the playgrounds we went.

Want More Content?

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!